Search This Blog

This blog is designed to help those who would like to set up a working HACCP Program for a warehouse.

Featured

- Get link

- X

- Other Apps

Receiving procedure for Food Warehouses

Keywords

Certificate

of conformity

A

document issued by a supplier showing that the supplied products meet a

specific criterion

Non-conforming

record

A

form in which details of products that don’t conform to quality standards are

recorded for traceability.

Non-conforming

area

A designated place in the storage area in which non-conforming goods are separated from the rest of the products while awaiting final disposition.

Receiving

Procedure

It is perhaps the most important of all warehouse activities. If

done wrong, it doesn't matter how well-handled other activities are - the

output will be non-conforming products. To explain this better, I will borrow a

computing phrase "garbage in, garbage out."

There are several quality checks carried out at the receiving stage, and these include; delivery truck inspection, food product inspection, and receiving area inspection. Remember, all these quality inspections target possible hazards identified during the hazard analysis in the HACCP Program.

The

delivery truck inspection;

Inspect the seal integrity for any form of tampering because it is proof

that the product has not been tampered with during transportation, and it is

safe from any form of sabotage.

A designated receiving personnel inspects the delivery truck for general cleanliness: looking out for visible dirt, pests, offensive odors, and any other possible contaminants that could pose a risk to the food product. In the case of temperature-sensitive products (chilled and frozen products), the delivery truck temperature is checked as well (from the temperature readout) for conformity to the set receiving standard as laid out in the HACCP program.

The

product inspection

Temperature-sensitive

products

The product temperature is measured using a clean

and sanitized calibrated thermometer. I advise using a probe thermometer as

opposed to the infra-red thermometer. The reason is simple- Infra-red

thermometer only measures surface temperature, yet the probe thermometer

measures the product's internal temperature, which gives a better understanding

of the temperature status of the products. However, when using a probe

thermometer, care should be taken not to pierce a product packaging as this can

be a source of contamination. The probe is placed between two primary packages

when taking the product temperature.

For a representative temperature status of the

product, the readings are taken repetitively during offloading. For a better

insight into the temperature of a particular product, pick samples from the

front, middle, and back of the product compartment.

For

delivery trucks with temperature monitoring devices, the data is downloaded and

checked to see if the product has been in a specified temperature range during

transportation.

Inspect the product cartons for sufficient expiry

date, proper labeling, and any damage sustained during transportation. Damaged

goods are non-conformed or put on hold for further inspections by designated

quality personnel.

A properly labeled product conforms to the following;

- Ingredients contained in the product.

- Health risks associated with the product.

- Storage instructions.

- Use by date

(expiry date).

Note; These are not

standard requirements for a product label, they can change depending on regulatory,

statutory laws, or client's needs.

The products must have an accompanying Certificate of Conformance

(COC) or Certificate of Analysis (COA) from the supplier. This certification is

evidence that the supplier followed all the statutory and regulatory rules

during the production of the product.

If

the food product deviates from any of the above criteria, it is labeled as a

non-conforming product and transferred to a designated storage area that meets

its storage instructions - Put chilled products in the chiller's non-conforming

area, and frozen non-conforming products into the non-conforming area in a

freezer. Record all non-conforming product details in a non-conforming form.

Please

note:

- The product should not have signs of prior

temperature abuse or signs of thawing and refreezing such as big ice

crystals in or on the product.

- The product temperature range is given by a regulatory body, a statutory body, or a client. But generally-chilling products are kept at 1°C-4°C and frozen products at -18°C (max < -12° C).

To know more about how to calibrate thermometer, check out this useful

resource; how-use-and-calibrate-probe-thermometer.

Dry

products and packaging material

Just like temperature-sensitive products, a dry product consignment must have a certificate of analysis or certificate of conformance. Check the dry products for sufficient expiry, damaged goods, proper labeling, and other contaminants that could make the product unsafe for consumption. Record all product details in the receiving form, and for the non-conforming products, their details are recorded in the non-conforming record.

Receiving

area

In the case of temperature-sensitive products, the receiving activities are carried out in a temperature control dock maintained at 1°C-7°C for not over one hour, but the warehouse management can choose a stricter temperature and time range.

Receiving

personnel

Designated receiving personnel must be knowledgeable about the

different receiving inspection, corrective actions in case of a deviation, and

the non-conformance procedure. The receiving personnel should be conversant

with documentation or record forms used in the receiving process.

Documents

used

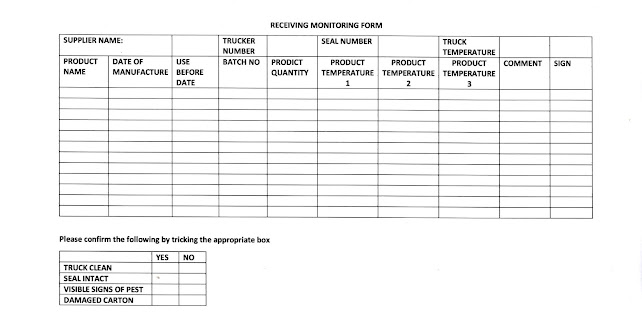

Receiving

Monitoring Form

Goods

Received Note

Certificate

of Conformity/ Certificate of Analysis

Non-conforming

form/record

Note: The receiving stage can be a Critical Control Point or a Critical Point depends on the individual company's Risk Assessment.

Check Appendix 1 and Appendix 2 for samples of

Receiving Monitoring Form and Goods Received Note, respectively.

Appendix 1

Appendix 2

or reload the browser

or reload the browser

or reload the browser

or reload the browser

or reload the browser

or reload the browser

or reload the browser

- Get link

- X

- Other Apps

Popular Posts

HACCP Program for Warehouse Handling Food Products- A simple Guide for Startups

- Get link

- X

- Other Apps

.png)

Comments

Post a Comment