Search This Blog

This blog is designed to help those who would like to set up a working HACCP Program for a warehouse.

Featured

- Get link

- X

- Other Apps

Warehouse Prerequisite Programs-Product Recall Procedure

A product recall is an action (s) taken to remove a

food product from the market at any stage of the food chain, including that

possessed by the final consumers. An efficient product recall process/program

involves numerous components that work in close connections to each other, these

include;

- Product Recall Team

- A complaint (trigger)

- Traceability

- Mock recall

- Product recovery and product reconciliation

- Final disposition

- Root cause analysis and Corrective action

Product Recall Team

For an efficient product recovery, assemble a

warehouse team responsible for product recall, outlining the unique responsibilities for

each individual (HACCP Team can double as a product recall team) such as one

responsible for communication to the clients, media, and statutory or regulatory

authority and the personnel responsible for product reconciliation and

disposition of the recovered product.

Complaint

A complaint is the most common trigger of a warehouse product

recall. It comes in various forms, such as a customer complaint and a

regulatory complaint. A customer complaint can be raised because of numerous

reasons such as;

- Contaminated product

- Health effects after consuming the product

- Expired product

- Wrong or misleading product labeling

- Sabotaged or adulterated product

Once a complaint has been raised by a customer, the warehouse customer care personnel records down various details of the product that will be vital for tracing and

identifying the consignment in question. These details include the following;

- Product name

- Product batch number

- Expiry date

- Date of purchase

- Customer location

- pictorial evidence (if required).

Traceability

As the name suggests, traceability has an element

of tracing, in this case, tracing for a food product through all the handling

processes of the warehouse.

Since this blog handles food products and other

related products like food packaging materials, we define traceability as the

ability to follow the history, application, movement, and location of an object

through specified stages of production, processing, and distribution.

There are two approaches to traceability;

one-step-back to the supplier of food products and one-step-forward (to the

consumer) approach.

As the most vital part of a product recall,

traceability plays a role in;

- Identifying product details like date of

receipt, amount, and batch number of the product in question or under

investigation received at the warehouse. Product details are in receiving records and Good Received Notes (GRNs).

- Identifying the amount of the consignment

under investigation that is still at the warehouse or that which was

dispatched to clients using documents such as Dispatch Monitoring Form and

Inventory Monitoring Form.

Mock recall

To test whether the established product recall of the warehouse is working and efficient, the product recall team at specific periods conducts a mock product recall.

Just like how fire drills prepare workers for actual fire incidents, the mock recall does the same for the recall

team of the warehouse in case of a product recall.

It's advisable to conduct a mock recall annually

and document every outcome, noting the failures and opportunities. These

(failures and opportunities) contribute enormously to the continuous improvement of the warehouse's product recall system or

procedure. A mock recall comprises but not limited to the following;

- The date and time the activity was initiated,

preferably after working hours when there are no other activities taking place at the warehouse.

- An overview of the records and documents reviewed to obtain the actual amount of a product recalled.

- A documented review by the product recall team that shows the mock product recall effectiveness including issues and opportunities for improvement, amounts of the food or a related product recovered, and outcome of the exercise.

In case the mock recovery exercise fails (less than

100% product recovered), it's advisable to repeat the exercise, correcting the

flaws within 60 days. However, the warehouse management can choose a much less

time frame depending on its operations.

Product recovery and reconciliation

The product recall procedure is based mainly on

documentation and the recording principle of the HACCP Program. Without proper

documentation of the HACCP program, there are minimal to zero chances of a successful recovery and reconciliation of food or a related product that was received, stored, or dispatched from the warehouse. For a product recall to be successful, all the

affected food product is recovered and withdrawn from the food chain.

Note:

The main objective of a product recall is to

prevent the consumption of food products that can pose health risks to the

consumers. It is done by locating deviant food products and promptly removing them from

the food chain and accurately communicating to the

affected customers as soon as possible about the product defect; the hazard associated with the product, and the

corrective action.

Final disposition

A product recall plan of the warehouse must

show the handling of the recovered products, and a procedure followed to track and control all the defective products returned to the warehouse.

The final disposition includes actions such as; returning the product to the

supplier or destroying all the deviant products.

Root cause analysis and corrective action

Root cause analysis ensures that a condition or a

set of conditions that led to the product recall is identified and understood

in-depth, gathering all the necessary information about the product. After

conducting a Root cause analysis comes corrective actions that eliminate the

cause of a non-conformity to prevent a recurrence.

Corrective actions include by are not limited to;

- Training staff

- Change of process

- Change of documents

Procedure

Assemble a product recall team for your

facility/warehouse. In case there is a HACCP team already in place, it can

serve as a product recall team with a few added individuals with well-defined duties or responsibilities. Just like

the HACCP Team, a product recall team must also have a leader responsible for

coordinating all activities of other team members. A product recall team includes but

not limited to the following;

- Warehouse decision-makers

- Marketing/ sale department

- Quality assurance department

- Customer care department

- Legal counsel

Develop a communication plan to reach out to all

stakeholders involved and should contain internal and external contact. The

internal phone contacts are those of the warehouse recall team that must always

be available 24/7. At minimal, the communication plan includes the following;

- When to Communicate to the media (If necessary or required by the law) and the person responsible.

- When to communicate to the authority or regulatory organs? If required by the local laws.

- When to notify the public or customers about the recall?

Identify the records and documents used to trace

the affected product at the warehouse, on the delivery truck, or delivered to

the final client. The identified records must contain all the

necessary product details that are vital in uniquely identifying the product in

question and these include but are not limited to;

- Goods Received Note

- Receiving Monitoring Form

- Inventory Monitoring Form

- Non-conforming Form

- Dispatch monitoring Form

Develop plans for withdrawing the affected product

(in case it's already dispatched from the warehouse) and separating the affected

products from the rest of the products in case the product is still in the

warehouse. These include non-conforming the affected product and recording the

product details in the non-conforming record.

Note:

A product recall can be voluntarily initiated by the warehouse management(voluntary product recall) or compulsory by the local authority after a questionable discovery regarding a particular product.

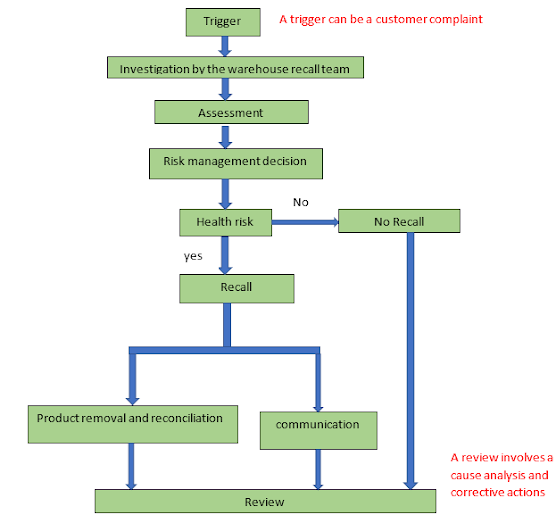

You can do a product recall for a warehouse following a decision tree below

or reload the browser

or reload the browser

or reload the browser

or reload the browser

or reload the browser

- Get link

- X

- Other Apps

Popular Posts

HACCP Program for Warehouse Handling Food Products- A simple Guide for Startups

- Get link

- X

- Other Apps

.png)

Comments

Post a Comment